source: How to Make a Clock Run for 10,000 Years | WIRED

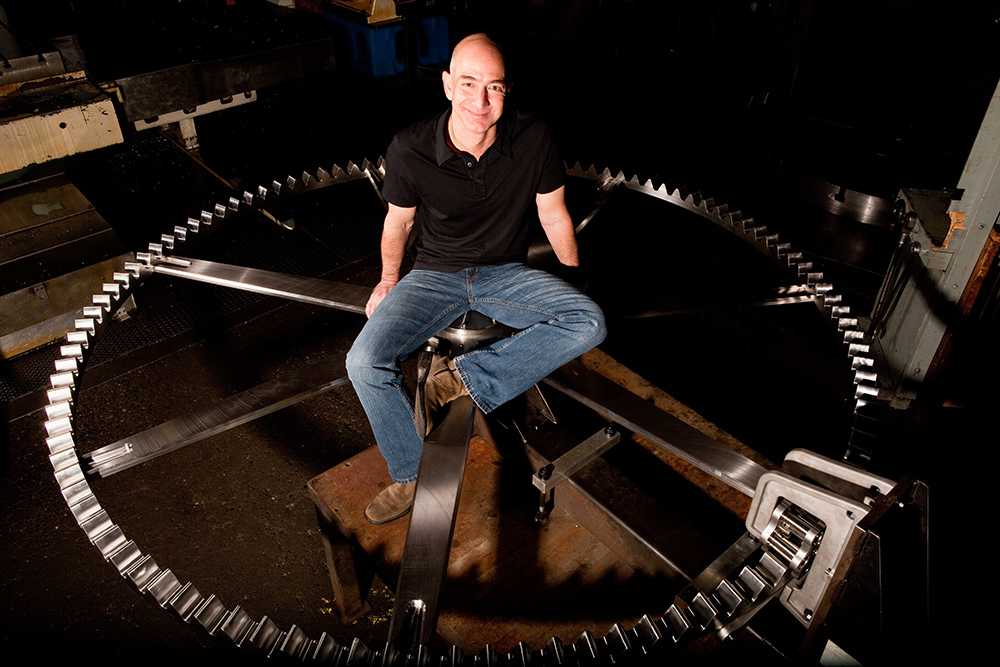

Billionaire Amazon.com founder Jeff Bezos has a long-term plan: to build a clock that runs for 10,000 years. (Photo: Jim Merithew/Wired.com)

High on a rocky ridge in the desert, nestled among the brush, is the topmost part of a clock that has been ticking for thousands of years.

It looks out over the ruins of a spaceport, built by a rich man whose name was forgotten long ago.

Most of the clock is deep inside the mountain, below the ridgeline. To get there, you hike for days through the heat; the only sounds are the buzzing of flies and the whisper of the occasional breeze. You climb up through the brush, then pass through a hidden door into the darkness and silence of the clock chamber. Far above your head, in the darkness, a massive pendulum swings slowly back and forth, making the clock tick once every 10 seconds.

‘In the year 4000, you’ll go see this clock and you’ll wonder, “Why on Earth did they build this?”‘ — Amazon CEO Jeff Bezos

No one knows who built it, or why. They built it well, and even now it keeps perfect time. All we know of these strange people is that they were obsessed with the future.

Why else would they build something that had no purpose except to mark time for thousands of years?

The rich man is Amazon.com founder Jeff Bezos, and he has indeed started construction on a clock that he hopes will run for 10,000 years.

For Bezos, the founder of Amazon.com, the clock is not just the ultimate prestige timepiece. It’s a symbol of the power of long-term thinking. His hope is that building it will change the way humanity thinks about time, encouraging our distant descendants to take a longer view than we have.

For starters, Bezos himself is taking a far, far longer view than most Fortune 500 CEOs.

“Over the lifetime of this clock, the United States won’t exist,” Bezos tells me. “Whole civilizations will rise and fall. New systems of government will be invented. You can’t imagine the world — no one can — that we’re trying to get this clock to pass through.”

To help achieve his mission of fostering long-term thinking, Bezos last week launched a website to publicize his clock. People who want to visit the clock once it’s ready can put their names on a waiting list on the site — although they’ll have to be prepared to wait, as the clock won’t be complete for years.

It’s a monumental undertaking that Bezos and the crew of people designing and building the clock repeatedly compare to the Egyptian pyramids. And as with the pharaohs, it takes a certain amount of ego — even hubris — to consider building such a monument. But it’s also an unparalleled engineering problem, challenging its makers to think about how to keep a machine intact, operational and accurate over a time span longer than most human-made objects have even existed.

Consider this: 10,000 years ago, our ancestors had barely begun making the transition from hunting and gathering to simple agriculture, and had just figured out how to cultivate gourds to use as bottles. What if those people had built a machine, set it in motion, and it was still running today? Would we understand how to use it? What would it tell us about them?

And would it change the way we think about our own future?

The idea for the clock has been around since Danny Hillis first proposed it in WIRED magazine in 1995. Since then, Hillis and others have built prototypes and created a nonprofit, the Long Now Foundation, to work on the clock and promote long-term thinking. But nobody actually started building a full-scale 10,000-year clock until Bezos put up a small portion — $42 million, he says — of his fortune.

Last year, contractors started machining components, such as a trio of 8-foot stainless steel gears and the Geneva wheels that will ring the chimes. Meanwhile, computers at Jet Propulsion Laboratories have spent months calculating the sun’s position in the sky at noon every day for the next 10,000 years, data that the clock will use to correct itself. This year, excavation began on the Texas desert site where the clock will be installed deep underground.

And just last month, the Smithsonian agreed to let the Long Now Foundation install a 10,000-year clock in one of its Washington museums, once they can find someone to fund it.

It seems that the time for millennium clocks has arrived.

The Project

Making a clock that will run for 10 millennia is no small undertaking. In Texas, the builders have started drilling a horizontal access tunnel into the base of the ridge where the clock will live. They’ll drill a pilot hole, 500 feet straight down from the top of the ridge, until it meets the access tunnel. Then they’ll bring a 12-foot-7-inch bit into the bottom and drill it back up, carving out a tall vertical shaft as it goes.

Afterwards, they’ll install a movable platform holding a 2.5-ton robot arm with a stonecutting saw mounted on the end. It will start carving a spiral staircase into the vertical shaft, from the top down, one step at a time.

The clock, with massive metal gears, a huge stone weight, and a precise, titanium escapement inside a protective quartz box, will go deep into the shaft. A few years from now, the makers will set it in motion.

Some day, thousands of years in the future, when Bezos and Amazon and even the United States are nothing more than memories, or less even than that, people may discover this clock, still ticking, and scratch their heads.

Bezos says, “In the year 4000, you’ll go see this clock and you’ll wonder, ‘Why on Earth did they build this?’”

The answer, he hopes, will lead you to think more profoundly about the distant future and your effects on it.

Here are some of the people who are creating the most temporally ambitious mechanical engineering project in human history.

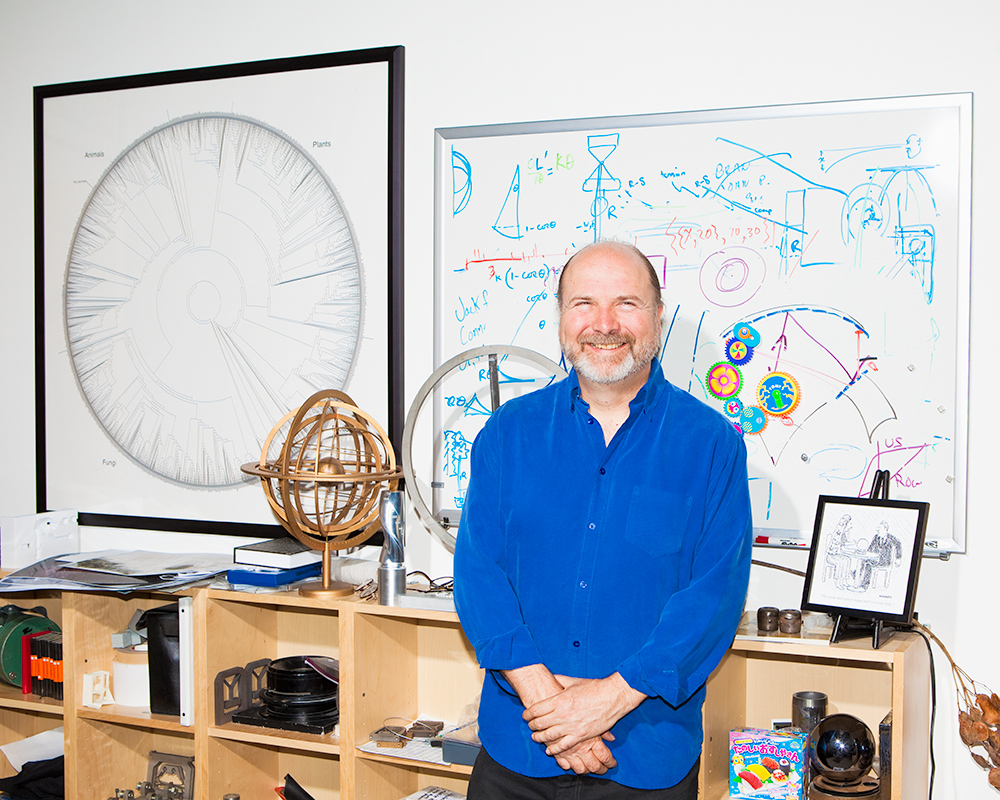

Inventor Danny Hillis first proposed the 10,000-year clock in WIRED in 1995, and has spent more than 15 years designing it. (Photo: Jon Snyder/Wired.com)

The Mastermind

I meet Danny Hillis in the well-stocked kitchen of his nondescript office building. After getting a cup of coffee and checking that I’ve signed his company’s NDA, he leads me into a closet.

‘The century hand advances once every 100 years, and the cuckoo comes out on the millennium.’ – Danny Hillis, inventor

An old-fashioned red phone booth is at the back. Hillis, a large, affable man with a graying ponytail and a salt-and-pepper beard, picks up the receiver and speaks into it: “The blue moon jumps over the purple sky.”

Suddenly, silently, the back of the phone booth swings open, revealing a white corridor. We walk through it into a big, well-lit warehouse. It turns out that Applied Minds is much bigger on the inside. Designers at computer workstations share the space with a 10-foot-high robot dinosaur, an enormous all-terrain expedition truck, a BMW motorcycle and bookshelves that are — inexplicably — leaning 15 or 20 degrees off vertical.

In fact, Applied Minds occupies five large one-story buildings here in a nondescript section of Glendale, a Los Angeles suburb. There’s no logo on the outside, nothing to indicate what’s behind the walls. Inside, however, it’s filled with improbable and amazing inventions.

The clock isn’t an official Applied Minds project. Most of what the company does is focused on solving an eclectic array of problems with the potential for commercial payoff. Google recently acquired an Applied spinoff called Freebase. Another spinoff, Applied Proteomics, is working on protein analysis machines to do early-stage cancer detection. Touch Table, a startup that makes large, interactive touchscreens seen on CNN and elsewhere, started here. Sun, Intel, Northrup Grumman and Herman Miller have all licensed Applied Minds inventions. NASA even contracted with Applied Minds to help design and build a mockup of a new lunar lander, which is still here, inside one of the workshops.

The clock, on the other hand, is a pure product of Hillis’ obsessions, and it’s profoundly uncommercial.

Hillis has spent more time thinking about time than just about anyone. Early in his career, he founded Thinking Machines, a supercomputer company built around his invention of massively parallel computing. Then, he was concerned with nanoseconds: The precise slivers of time needed to synchronize tens of thousands of microprocessors working together.

But for the past 15 years, he’s also been obsessed with millennia.

It was this obsession with the future that led Hillis to pen the Wired.com essay where he first laid out the idea of a clock that would run for 10,000 years. “I want to build a clock that ticks once a year,” he wrote. “The century hand advances once every 100 years, and the cuckoo comes out on the millennium.”

In 1995, just as people were starting to get excited about the internet, it seemed like a crazy idea. Marvin Minsky and Jonas Salk warned him off it. Few understood how one of the era’s greatest technologists could turn from supercomputers to 19th century technology. As late as 1998, people were expressing concern that a mind of Hillis’ caliber was being wasted. (His four-year stint as the head of R&D at Disney probably didn’t help that impression.)

Still, a few people latched on. Then-Wired editor Kevin Kelly took to the idea. Stewart Brand loved it and helped set up the Long Now Foundation to help further the clock and, more generally, the idea of thinking about the long-term future. And Hillis continued to evaluate the construction problems, come up with design criteria and sketch ideas for how to build it.

The clock’s escapement is a delicate-looking but durable contraption made mostly of titanium that ticks once every 10 seconds. It will be housed in a quartz box, to keep dust out. (Photo: Jon Snyder/Wired.com)

Hillis is easily the most approachable genius I’ve ever met, with a boylike enthusiasm, smiling eyes and an office full of fascinating and mostly neglected scientific tools. Everyone calls him “Danny.” And why wouldn’t he be happy? He’s free to give his mind free range, and he’s surrounded by awesome toys and very smart people. He’s found a way to make the most of his talents, and that’s partly by attracting others to his projects.

“My trick is, I collect up people who I can learn from, and enable them so that they hang around me,” Hillis tells me.

It’s clear that the clock is, in some ways, an excuse for Hillis to pursue his interests. He ticks off the topics he’s needed to study while working on the clock, and I scribble them down as fast as I can: mechanical engineering, chemical engineering, optical engineering, clockmaking, material science, geology, astronomy, anthropology, biology, paleontology, storytelling. (I may have missed a few.) All have figured into the problem set of making a clock that not only runs accurately for 10,000 years, but also means something to those who come upon it.

“I’ve always been a kind of science groupie,” Hillis says. Working on the clock — like working with supercomputers — lets him delve into a wide variety of scientific fields, educating himself as he goes. “For me, making the clock is almost a mental vacation. It’s a different way of thinking. It’s very relaxing.”

By way of illustration, he tells me how he’s been studying ancient eclipse records and the growth rings on fossil mollusks, both of which might provide more accurate data on how the Earth’s rotation is slowing.

A 6-foot long, 300-pound titanium pendulum regulates the rate at which the escapement clicks, keeping it at a steady one beat per 10 seconds. (Photo: Jon Snyder/Wired.com)

That’s all very nice for Hillis, but what about the rest of the world? I ask him how he can justify spending time on the clock instead of, say, Applied Proteomics, which is helping fight cancer.

“I think this is the most important thing I can work on. More than cancer. Over the long run, I think this will make more difference to more people,” he says.

He hopes people will become interested in the idea of the clock, as I have. They’ll want to see it, and they’ll start thinking about why someone would make it.

“Then they’ll start thinking more skeptically,” Hillis says. They’ll start thinking about what the world might look like in 10,000 years, whether the country will still be here, what the climate will be like, what kinds of tools people will be using, whether our cities will look the same. “As soon as you start thinking that way, you open up a whole new field of thought,” Hillis continues.

“If it just does that for a tiny percentage of the people who hear about it, then I think that’s worth it,” he says.

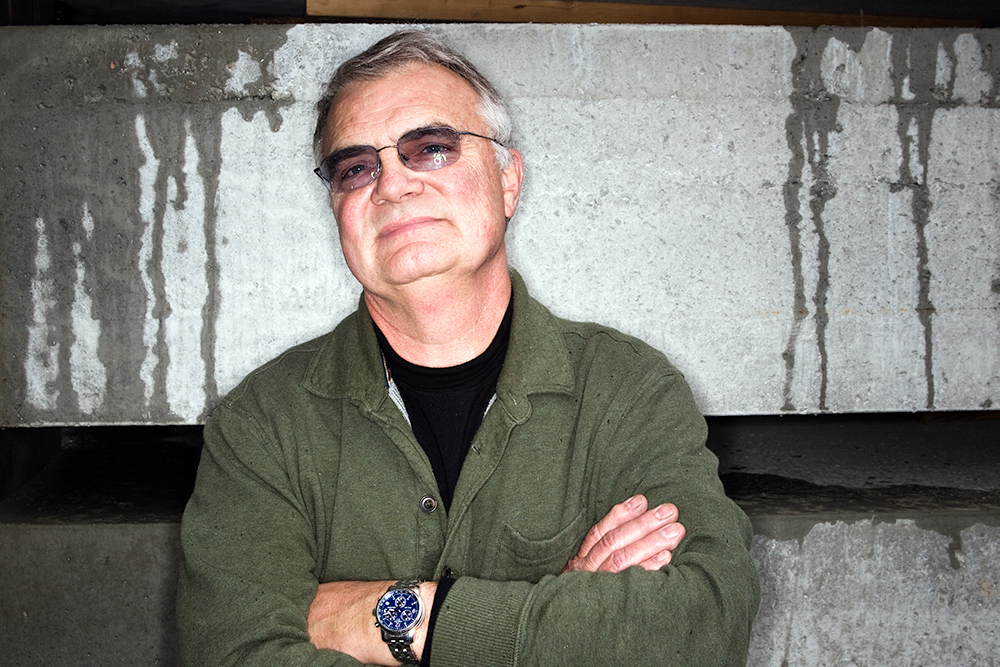

Alexander Rose is the meticulous engineer and manager of clock project. He grew up in a junk yard — who could be more qualified? (Photo: Jim Merithew/Wired.com)

The General

Alexander Rose’s childhood might have given him a unique preparation for working on the clock: He grew up near the Arques shipyard in Sausalito, finding junk, tearing it apart and reassembling it.

“Living in a junkyard, how could you not build stuff?” he says. With his friends, he made bicycles, bombs, rockets, ziplines and forts.

The junkyard might also have given him a special appreciation for how machines fall apart, a perspective that’s handy when you’re trying to make something work for a long, long time.

So when it was time to get serious about building the clock, Rose was ready.

Rose, known to many as “Zander,” has a reserved, analytic demeanor that’s accentuated by his shaved head and piercing gaze. It’s obvious he enjoys his work, though, and I suspect his taste for mechanical experimentation has gotten him in trouble more than once.

In high school, he volunteered with Survival Research Laboratories, which builds dramatically destructive robotic machines and then pits them against one another in loud, chaotic performances of mechanical violence.

Then, in 1996, Rose and his friends started building combat robots. Their robots eventually won six championships and scored them appearances on the BattleBots show produced by Comedy Central.

“Destructive testing is an interesting kind of accelerated aging,” Rose says. “Three minutes in that arena is like 1,000 years anywhere else.”

Rose plowed the money from his TV contracts and action figures of his robots into a nice machine shop in Sausalito, in which he and a friend set up a business making and selling wheeled robot platforms (such as the Surveyor SRV-1) and, lately, robotic boats.

But since 1997 Rose’s primary job has been as the director of the Long Now Foundation. He was the foundation’s first employee and has done much of the work of translating Hillis’s concepts and schematics into working prototypes objects.

Running the Long Now Foundation means helping organize its events and seminars, overseeing its membership and recruiting supporters. But Rose’s primary job is managing the vast, complex clock project.

In the early days, that meant working with Hillis to sketch out and test ideas for how the clock might work. Eventually, that work culminated in a beautifully machined prototype clock, which started ticking on New Year’s Eve, 1999 and now stands in the Science Museum in London. Rose then oversaw the building of other prototype components, such as the mechanical computer that sequences the clock’s chimes, the orrery and the solar synchronizer, which are on display in the Long Now Foundation’s San Francisco office.

At first, Hillis and Rose and other members of the foundation figured the organization’s primary job would be building the clock. They even purchased a remote site, in Nevada, which met their geographic, geological and meteorological needs.

But then progress seemed to stop — at least from the outside. Although the Long Now Foundation continued working on prototypes, materials testing, design and other projects, media attention faded after the turn of the millennium. To anyone not part of the project, the clock seemed to have become one of those ideas that are good to think about, but impractical in reality.

Then Bezos and Hillis, already good friends, got to talking.

Bezos was already used to taking the long view. Hillis seems to have encouraged him to think on an even larger time scale. Bezos co-sponsored Long Bets, a forum for making and debating long-term predictions that WIRED covered extensively in 2002. Then, around 2005, the pair got serious and started making plans to build a clock on Bezos’ property.

Fortunately, the previous 10 years had been a good preparation. The Long Now Foundation had grown into a small but sustainable organization of similarly obsessed people, with over 3,300 members contributing $8 a month to support long-term thinking. The prototypes told them much about materials and techniques they’d need to use. And Rose had grown into a skilled manager of insanely complex and long-term projects.

It turns out that Rose is a good person to have on your team with a project like this. He’s a skilled engineer, a thoughtful spokesman and a bit of a showman. But he’s also the kind of person who likes figuring out logistical problems. Such as: How do you carve a spiral staircase 500 feet down into the limestone of a remote desert ridge?

The answer, characteristically, is a giant robot.

“My background is in battle bots,” he says. “I never thought that would come together with the Long Now Foundation. But here I am, building a chainsaw-wielding robot.”

Master stonecutter Stuart Kendall will cut a spiral staircase into the underground chamber where the clock will reside. (Photo: Jim Merithew/Wired.com)

The Stonecutter

Stuart Kendall was standing on top of the Great Pyramid in Egypt in 1976, when it came to him.

He looked down at the 4,500-year-old, man-made mountain of stone beneath him, and said to himself, “God, I’d give anything to be involved in a project like this.”

A mechanical improviser with a sense of history and a knack for hacking together odd but extremely effective machines for special purposes, Kendall would have to wait 30 years for a project that could stand on its own with the pyramids.

Like the pyramids, the key was stone.

After Bezos decided he wanted to fund the construction of the first clock and volunteered his Texas ranch as a possible site, the clock team started scouting the property.

They eventually settled on a ridge above the headquarters of Blue Origin, Bezos’ secretive space startup. Made out of dolomitic limestone, the ridge is a solid fin of rock jutting into the sky above the flat desert. It has every characteristic Hillis was looking for: hard rock, seismically stable, south-facing exposure, a challenging but not impossible approach.

Hillis knew the clock would need to be located underground in a remote location, in order to protect it through centuries of human and environmental threats. But it also needed to be at least somewhat accessible to humans, otherwise what was the point? So the design called for a spiral staircase rising up through a deep underground chamber. That’s when they came to Kendall, who is renowned for his stonecutting skills.

Kendall got obsessed with rock in the 1980s while on vacation in Germany, after seeing a large stone sphere floating on a bubbling cushion of water.

“I said, ‘I’ve got to find a way to do this myself,’” Kendall says.

Kendall is a solidly built man with unruly gray hair and a stutter that occasionally grabs hold of him mid-sentence, halting his speech for a moment as he wrestles down the next word. But the stutter never stops him for long, and he can talk enthusiastically for hours about his favorite projects.

He studied opera in college and has worked as a blacksmith, museum exhibit designer and machinist. He’s preternaturally handy when it comes to building special-purpose machines, so he applied that thinking to the stone spheres. Using salvaged parts and second-hand equipment, he built a computer-controlled stonecutting rig that has nine axes of control and can cut and polish granite into extremely smooth, perfectly round spheres. It’s the only machine of its kind in the United States.

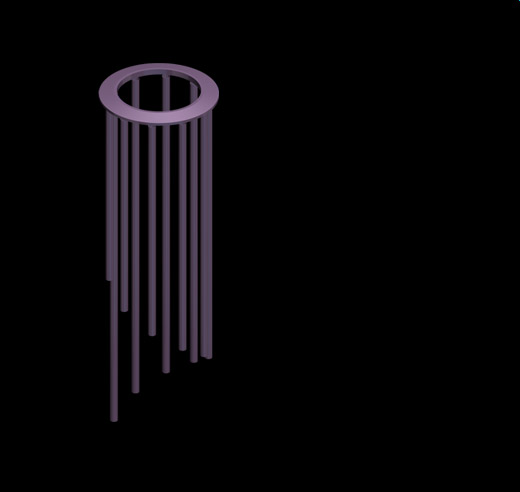

Kendall designed a giant robotic arm with a stonecutting saw to slice steps out of solid rock. (Photo: Jim Merithew/Wired.com)

Since then, he’s made 15 floating rock spheres, mostly for rich clients in the Pacific Northwest, but occasionally for public spaces. Kids love to play with them, since the enormous mass of the spheres gives them an unusual degree of momentum. It’s also a bit mysterious how the water pressure alone can float such a huge object, enabling it to spin like a ball bearing.

The spheres turned into a business, Seattle Solstice, and earned Kendall a glowing reputation among Pacific Northwest billionaires. (If you want to buy a floating sphere for your own villa or chateau, it will cost you about $100,000.)

But the clock project gets him charged up like no other.

“This has been the most exciting, crazy project I’ve ever been on,” says Kendall. “It’s like I’ve been training for this my whole life.”

For the clock’s staircase, Kendall’s solution is a giant robot arm with a stonecutting saw on the end. Once the vertical shaft has been drilled, this arm will be placed on a movable platform in the center of the shaft. Following instructions coded into its computer, the saw will cut through the stone, carving out deep gaps between slices of rock a couple inches thick. Workers will knock out the remaining slices, remove the rubble and expose a single step. Then the platform will move down a few inches and the saw will cut the next step. Repeat that process for a year, or less if you’re lucky, and you’ll have a 500-foot spiral staircase cut out of solid limestone, diving deep into the earth.

Robotic Stone Saw testing and simulation from The Long Now Foundation on Vimeo.

When we visit Seattle Solstice, the team is in the process of testing the saw on a big block of concrete. It sounds like a jet engine. And then it starts cutting through the concrete, and it gets really loud. Waaahhhh …. waaaaahhhhh….. waaaaaaAAAAHHH goes the saw, pulsing through the stone. Gray water, loaded with rock slurry, is all over the floor below. After an hour or two, it has sliced a narrow horizontal channel several feet into the block.

Nobody has ever built a stonecutting rig like this before, and Kendall is justifiably proud of it. But he’s not doing the clock project just for the fun of building robots.

When I ask him about his motivation, Kendall repeats a story about New College in Oxford, whose 14th-century builders planted oak trees that they knew would be ready, 500 years later, to replace the hall’s roofbeams when the time came. (The story appears in Hillis’ original 10,000-year clock article, and I’ve heard several people connected with the clock project retell it. And why not — it’s a great story.) That kind of long-term thinking is sadly lacking in the modern world, Kendall maintains.

It’s not surprising that a guy who works in stone is disenchanted with the throwaway nature of modern American culture. It is striking, though, to see how completely Kendall — like many others — has been drawn so completely into this project’s absurdly long time horizon. Taking the 10,000-year view is so ludicrous that it either strikes people as completely silly and irrelevant, or else it grabs hold of you and won’t let go.

For Kendall, as for others, it’s not letting go.

Chris Rand is one of several machinists who cut, polish and assemble the clock’s large steel components. (Photo: Jon Snyder/Wired.com)

The Machinists

Once they’ve drilled holes into the mountain, the builders will start assembling the clock in place.

‘I believe long-term thinking is an extraordinary lever that lets people accomplish things they couldn’t do otherwise.’ – Amazon CEO Jeff Bezos

But first, they need to fabricate its components.

“A lot of the way the clock manages to run for a long time is by using good materials, making parts really big and making them move slowly,” says Hillis. So for longevity, most of the clock’s major components are made of either 316 stainless steel (.pdf) or titanium.

On the other hand, says Rose, “The point of this project is to impress people visually as much as to work. People have to be amazed by it for it to fulfill its social function.”

Both of those needs point in one direction: Giant shining metal gears.

For that, you need men (and they mostly are men) like Chris Rand and Dave Miner, proud bearers of a dwindling trade. They are machinists who know how to carve and polish steel to micrometer tolerances and who relish the challenge of working on a large scale.

Miner is a 27-year employee of Machinists Inc., a Seattle machine shop. He has a dark gray mustache, dark gray hair and a diffident manner. At Machinists Inc, he spent 10 years working on a laser at Lawrence Livermore National Laboratory, and has worked on countless projects for Boeing, the area’s biggest employer of machinists.

Dave Miner has been cutting metal for over 25 years at Machinists Inc., a Seattle machine shop, and is now working on the clock’s Geneva wheels. (Photo: Jim Merithew/Wired.com)

Rand is younger, with a sandy goatee. A longtime collaborator of Rose’s, he did much of the work of building the prototype clock that’s now in London. In an earlier phase of his career he helped craft racing boats for the America’s Cup, then built models at Industrial Light and Magic (including a land speeder used in Star Wars). Now he runs the shop in San Rafael, California where all the clock components will be assembled in sections and tested before being shipped to Texas for installation.

“This project fits me personally like none other I’ve ever worked on before,” says Miner. “I’m a gearhead — and that’s what this clock is all about.”

For instance, there’s the 700-pound, 8-foot-diameter stainless steel gear wheel that’s sitting in the shop on the day we visit. (It’s the wheel that Bezos is sitting on in this story’s first photo.) It’s set up horizontally, and despite its weight, I find I can turn it easily with the push of a finger. Once installed in the clock it will be oriented vertically, with two others just like it, and linked to a metal “spine” that will support the clock’s heavy stone weights. As the weights fall slowly, the spine will engage, through mechanical connections, with smaller titanium rollers that mesh perfectly with the 8-foot wheels’ teeth. The wheels will then transfer the power to other parts of the clock.

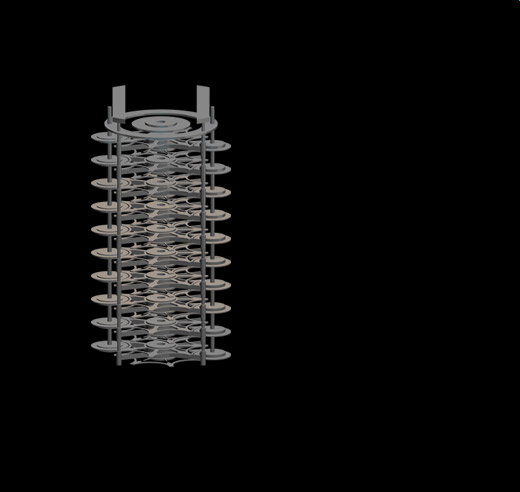

This stainless steel Geneva wheel is one of 20 similar wheels which together make up the clock’s chime computer, generating a different tune almost every day for the next 10,000 years.

Then there are the Geneva wheels, part of the clock’s chime computer. There are 20 wheels, with varying numbers of teeth (7, 9, 10 and 12). Their rotation combines in such a way as to compute a unique sequence of chimes: 3.65 million possible tunes, all unique. That’s about 90,000 fewer tunes than there are days in 10 millennia, but, Rose deadpans, “The chimes only ring on days when people are there, so we figure they won’t notice the difference if we repeat a few.”

To make the Genevas, Miner and his team had to cut 120 total spokes. They rough-cut them from steel blanks with water jets, then machined each spoke to precise tolerances on CNC milling machines. Each spoke weighs about 75 pounds when complete. The spokes are then shipped to San Rafael, where Rand’s crew assembles them into wheels for testing.

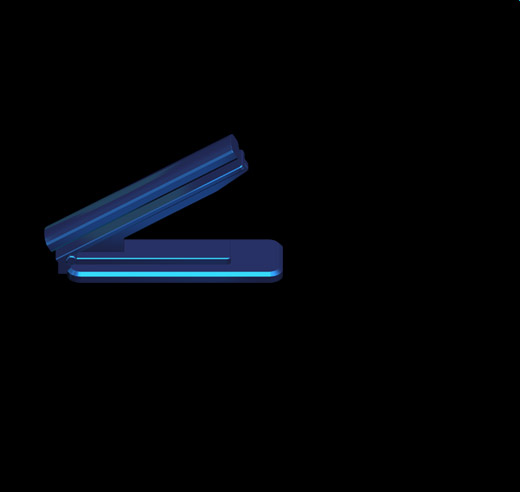

The clock’s wheels spin on top of bearings composed of a type of ceramic that will never need to be lubricated. (Photo: Jim Merithew/Wired.com)

All of the wheels rotate on bearings made of zirconium nitride ceramic. Aerospace engineers originally developed this type of bearings for use in the satellite industry, because they needed something that would roll reliably without lubrication (you can’t use oil in space, where it would evaporate). Ceramic bearings were prohibitively expensive at first, but started showing up in rollerblades, and their price is coming down. They’re ideal for the clock because they don’t need lubrication, and because they help minimize the amount of contact between different types of metal. Otherwise, over time, galvanic reactions would cause the metal-on-metal touch points to corrode, and that’s obviously something the builders want to avoid.

“Things that have short-term planned obsolescence really bug me now,” says Rand. He points to a 30-year-old Bridgeport milling machine in his shop, still as solid as ever, and praises American cars from the 1950s and 1960s. Now, he says, cars only last a decade at most. “It’s getting harder and harder to buy quality stuff.”

Standing in his machine shop next to a modern, computer-controlled CNC machine, Rand shifts to the oral traditions of Native American cultures, saying the clock has given him a new appreciation for their views.

“They had a time view looking forward six or seven generations. They’d ask themselves, ‘How are my actions going to affect my great-great-great grandchildren?’ You’d never find them going in and cutting down a whole forest.”

Amazon CEO Jeff Bezos has budgeted $42 million for the clock project. Why? Because nobody else is going to do it, he says. (Photo: Jim Merithew/Wired.com)

The Patron

To build a clock, Hillis and the Long Now Foundation needed a sponsor whose sense of scope matched their own.

They found that in Amazon.com founder Jeff Bezos. He’s rich enough, he’s thoughtful enough, and he’s focused on the distant future — the very distant future.

“I believe long-term thinking is an extraordinary lever that lets people accomplish things they couldn’t do otherwise,” says Bezos.

To illustrate this, he poses a problem. Suppose he challenged you to solve world hunger in the next 5 years. It would be unsolvable: There is simply no way to fix a problem of that magnitude in a few years. But given 200 years? You might have a chance.

More importantly, you would start thinking about the problem differently. You’d do different things. Your whole orientation would change, because your actions would be directed not at your contemporaries, but at people to come a century or two from now.

In the same way, Bezos wants to build the clock for people who have not yet been born, for our great-great-great grandchildren.

It’s not a new fad for him. The same kind of thinking is embedded in Amazon.com’s first statement to its shareholders in 1997 (.pdf), and in every annual shareholder letter since then. “It’s all about the long term,” that letter stated. “Because of our emphasis on the long term, we may make decisions and weigh tradeoffs differently than some companies.”

Bezos is shorter than I expected him to be, and balder. He’s wearing blue jeans, a black polo shirt and a leather jacket, and he speaks with a kind of deliberate intensity that shows he’s giving his words great thought — and isn’t accustomed to being interrupted. He pauses, thinks, and then states what he thinks in long, articulate sentences.

And then there’s his laugh. Totally unexpected, and a bit alarming, it explodes out of him at surprising moments. I can tell he’s enjoying himself, talking about his clock, but his laugh unnerves me a little.

“My opinion is that human attention spans haven’t changed much over time. We’ve always been a fairly short-sighted species,” Bezos says, and laughs. “But while our attention spans are staying roughly constant, our problems are becoming much bigger, because of our past successes as a species. Our tools, our technologies, now require us to step it up, and have a longer attention span.”

Still, I ask Bezos how he can justify spending so much money on a project that seems so, well, impractical. He’s budgeted $42 million, but expects it the cost will run over somewhat. Maybe that’s not much for the 18th richest person in America (it’s just 0.3 percent of his fortune) but it’s still a lot of dough. In reply, Bezos tells me the same thing Hillis did: Long-term thinking is important enough that, relative to the benefit, the clock is well worth the expense.

But there’s a second reason, he says: It’s nonredundant. Bill Gates is funding malaria research and education, George Soros promotes human rights around the globe, Warren Buffett gives to reproductive health, family planning, and antinuclear causes. But no other billionaire is building a clock like this, for the sole purpose of changing humanity’s relationship to time.

“If you think something is important, and you think nobody else is going to do it, then it’s a useful thing to do,” Bezos says.

And then there’s the personal dimension, the same thing that, at bottom, motivates Hillis, Rose, Kendall, Miner and Rand. It’s a beautiful challenge.

“Because it’s a challenging engineering problem, I’m also just delighted by it,” says Bezos. “It’s really never been done before at this scale. All of those technology challenges for me are titillating.”

Hillis has his own explanation, and, like Kendall, it goes back to the Pyramids.

“Everybody has a picture of the Pyramids in their mind, and it sort of connects you to the past,” says Hillis. “We don’t have anything like that for the future. We don’t have a symbol that connects us to the future. I think the world needs that, just for the joy of it, because it makes us more human to have that connection to the future.”

Now it looks like, as the Long Now Foundation had always hoped, the clock will be merely the first in a series of millennium timepieces. The foundation plans to make the designs for the clock open source, so eventually you’ll be able to download plans and schematics to build your own. If they can find someone to foot the bill, the foundation will install a second clock in one of the Smithsonian museums in Washington, D.C. And there’s still the site in Nevada, which could eventually get a clock of its own.

“It’d be nice,” Hillis says, when I ask him if there would be more clocks like this. “Pyramid building sort of caught on.”

The team this year began excavation on a site in West Texas overlooking the Blue Origin spaceport. A spiral staircase will lead down to the 10,000-year clock kept underground.

The Future

Below the clock, there will be a spaceport. Not much is known about Blue Origin, the private space venture that Bezos is backing, other than a few tidbits. The company is working on rockets that take off and land vertically, just like the rockets in 1950s science fiction movies, and has published video of an early test. The goal is to develop a vehicle capable of taking people into orbit.

While other rich men’s space startups, such as Richard Branson’s Virgin Galactic and Elon Musk’s SpaceX, have loudly trumpeted their major milestones, Blue Origin has been quiet. There’s a launch complex, and the company has secured permission from the FAA to launch rockets there. But what goes on inside Blue Origin’s handful of low white buildings is still a mystery. Visitors can’t even get anywhere near it, thanks to the size of Bezos’ property.

Bezos doesn’t tell me much about the company, though he does say that the connection between the clock and the spaceport has no practical reason — it’s just a cool coincidence.

“Poetically, I think it’s very nice that a 10,000-year symbol is looking out over a launch complex designed to help get people into space,” says Bezos. “I think we can all agree that a little poetry is nice.” And then there’s that laugh again.

To get to the clock, you’ll need to hike half a day to the base of the mountain in which the clock is embedded. You’ll walk up into a narrow notch of stone, coming at last to a door made of stainless steel with panels of green nephritic jade. The door leads into a tunnel, which ends at the base of the vertical shaft, in darkness. Taking a flashlight to see, you’ll start climbing up the spiral staircase, winding around the outer wall of the shaft, going past various parts of the clock as you go.

One of the first sections you’ll pass is the power train, with huge suspended stone weights and a capstan that you can turn to raise the weights and wind the clock. Once wound, the energy of these weights will help power the clock and its chimes.

You’ll then walk past the mechanical computer (a complex collection of gears and linkages) that rings the clock’s chimes, and a bit further up, the actual chimes.

If it’s been wound, the clock will ring the bells once a day, playing a different tune each time. The mechanical computer will rearrange the notes to create a unique melody for almost every one of the next 3,650,000 days. (Musician Brian Eno is helping compose the music the chimes will play.)

The clock itself will be impressively huge and mechanical, with giant gear wheels made out of stainless steel turning on ceramic bearings, as well as smaller pinions made out of titanium. There will be no way to see it all at once — you’ll have to climb through a couple hundred vertical feet to see all its parts, one by one, ending at the clock face in the uppermost room.

The clock will keep perfect time on its own, ticking quietly once every 10 seconds, with a 6-foot, 300-pound titanium pendulum slowly feeding the energy from the weights into the clock’s escapement. A cupola at the top of the ridge will collect solar energy to feed the power train; it will also use sunlight to synchronize the clock with solar noon whenever the sun is shining. (Fully wound, the clock should be able to run for over a century without solar power.) To conserve energy, and to encourage visitor participation, it won’t actually display the current time on its face most of the time. Instead, the face will show the time and date (and the corresponding position of the stars and planets) of the last person’s visit to the clock, whether that was yesterday or 300 years ago. If you want to view the current time, you’ll need to turn a wheel near the clock face, which advances the clock’s dials, moving through time until it automatically clicks to a stop at the present moment:

Now.

The idea behind all this elaborate mechanical wizardry, in addition to engineering something that will run reliably for millennia, is to awe people, making them pause and encouraging them to think about their own distant future.

At the end of our interview, I walk with Bezos back to the machine shop. He looks over the gears and components they’ve laid out for us to photograph, talks with the machinists, gets an update from Rose, and we take his portrait. I thank Bezos for showing me his crazy project, and he stops to correct me.

“This is the sanest thing we’ve ever done,” says Bezos, before leaving.

I’m left there in the machine shop in Seattle, my fingertips turning a giant gear wheel that, if everything goes well, will still be slowly turning long after I’m gone.

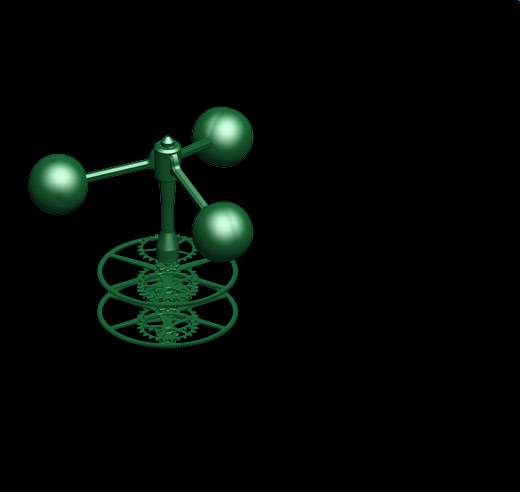

sidebar: Clock components

Main power system

The main power storage for the clock is a large weight hanging on a rack gear. The weight can be wound both by visitors to the clock, as well as the solar winder. The power from this system is used to ring the chimes on any day it is fully wound. The rest of the time it powers the time- keeping mechanism, and has enough power to run the clock for many years without any human winding or sunlight.

Governor

Energy coming out of the power system is geared and moderated by a speed governor which only spins up when the chimes are ringing.

Chime Generator

The chime generator is a mechanical computer that rings ten bells in a differ- ent order each day for 10,000 years. The generator is made up of a cascading series of Geneva wheels which create intermittent motion (a bell ring) out of continuous rotation (from the main power system).

Chimes

The ten bells or chimes used in the clock are not yet designed. Once the acoustics of the space have been measured, several materials and bell designs will be tested before installation.

Timing system and Display

Energy from main power system is fed into an escapement that powers a slow moving titanium pendulum. This day-to-day time keeper is kept from drifting by corrections from the Solar Synchronizer.

The displays are made up of a series of dials, planetaria and mechanical calen- dars. Visitors update these dials by winding a wheel in the dial chamber which stops when the dials reach the present moment. The clock always knows what time it is, but only shows you when you wind it.

Solar Synchronizer and Clock winder

Sunlight allowed into the top of the mountain through a south facing synthetic sapphire window heats up a chamber of air moving a graphite cylinder. This gives the clock a solar noon correction signal as well as enough winding force to keep the pendulum ticking.

This schematic shows the major components of the 10,000 year clock, with arrows showing how energy flows from one part to the next. Illustrations and captions courtesy of the Long Now Foundation.